研究室の目標/Our mission

持続可能な農業生産システムの創出/Creation of sustainable agricultural production systems

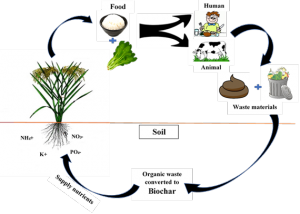

農業生産は人類の生存を支える基盤であり、これからの人類の繁栄にも欠かせない重要な営みです。一方で、地球規模での人口増加や経済発展に伴い、地球環境と調和した農業生産の実現は難しくなっています。経済性と環境保全が両立する持続可能な農業生産システムの創出には、再生可能資源であるバイオマスの生産と利活用を中心とした物質循環システムの構築が鍵となります。この目標に向け当研究室では、1)環境負荷の少ない作物生産技術の開発、2)高品質な有機肥料の製造および機能性成分の抽出、そして3)バイオエネルギーの生産に資する教育研究を進めています。こうした教育研究活動を通じて、持続可能な農業生産システムの創出と、高度な専門知識と論理的思考能力、コミュニケーション能力を有した次世代を担う人材育成に貢献します。

Agricultural production is the foundation that supports the survival of humankind and is an important activity that is essential for the future prosperity of humankind. On the other hand, as the global population increases and economic development progresses, it is becoming increasingly difficult to achieve agricultural production that is in harmony with the global environment. The key to creating a sustainable agricultural production system that is both economical and environmentally friendly is the construction of a material circulation system centered on the production and utilization of biomass, a renewable resource. Toward this goal, our laboratory is conducting education and research that contributes to 1) the development of crop production technology with less environmental impact, 2) the production of high-quality organic fertilizers and the extraction of functional components, and 3) the production of bioenergy. Through these educational and research activities, we contribute to the creation of sustainable agricultural production systems and the development of human resources for the next generation who possess advanced expertise, logical thinking and communication skills.

研究課題一覧/Projects

炭化技術を軸とした廃棄物系バイオマスの統合的管理技術の開発/Development of integrated management technology for waste biomass based on carbonization technology

家畜排せつ物や食品残さなどの廃棄物系バイオマスは,国内で毎年1億トンを超える膨大な量が生み出されています。廃棄物系バイオマスは温室効果ガスや悪臭,そして富栄養化などの発生源となりうるため,適切な管理が必要となります。しかしその一方で,含水率が80%を超えることもあり,取り扱いが難しく,それらの再資源化やエネルギー化は簡単なことではありません。

この研究では廃棄物系バイオマスを省エネルギーな方法で炭化し,バイオマス由来の炭(バイオ炭)へと変換することで,バイオ固形燃料や土壌改良剤として利活用することを目指しています。

Waste biomass, such as livestock and food waste and food, is produced in Japan in enormous quantities, amounting to more than 100 million tons every year. Waste biomass is a potential source of greenhouse gases, odors, and eutrophication, so it must be managed appropriately. On the other hand, the moisture content of waste biomass can exceed 80%, making it difficult to handle and difficult to recycle or convert into energy.

In this research, waste biomass is carbonized in an energy-saving way and converted into biomass-derived charcoal (biochar), which can be utilized as bio-solid fuel or soil conditioner.

1.省エネルギーな炭化技術の開発/Development of energy-saving carbonization technology

炭化はバイオマスを350℃以上で熱分解し,炭素含有率の高いバイオ炭へと変換する技術です。しかし,熱分解やその前に行われる乾燥プロセスでは多くの化石燃料が使用されることになります。したがって家畜排せつ物のような高水分材料に対しては炭化はもとより,乾燥すら積極的に行われていないのが現状です。こうした状況を変えるため,本研究室では,有酸素雰囲気のもと,従来の炭化よりもはるかに低い温度域(90℃)でバイオマスの炭化を行うことを目指しました。その結果,低温でもバイオマスは炭化プロセスと似た分解が進むことを確認し,最終的には泥炭(石炭類の一種)と似た物質にまで品質を向上させることに成功しました(Itoh et al., PLoS ONE, 2018)。

また,廃棄物系バイオマスの自己昇温反応を利用した炭化技術の開発(自己発熱型炭化法)も目指しています(Itoh et al., Waste Management, 2019)。現在はバイオマスの自己昇温が起きる反応条件や,作成されるバイオ炭の理化学的性質を調べている段階です(Itoh et al., Plos ONE, 2020)。この方式では炭化に必要な熱源を原料内部から抽出して行うため,化石燃料を使用せずともバイオ炭の製造を行えると考えられます。このように自己発熱型炭化法は,従来の炭化の概念を大きく変える画期的な技術であると期待し,研究を進めています。

Carbonization is a technology that converts biomass into biochar with a high carbon content by pyrolysis at temperatures above 350°C. The process is called “carbonization” in Japan. However, pyrolysis and the drying process that precedes pyrolysis use a large amount of fossil fuels. Therefore, not only carbonization but even drying of high-moisture materials such as livestock waste is not actively conducted at present. In order to change this situation, this laboratory aimed to carbonize biomass at a much lower temperature range (90°C) than conventional carbonization under an aerobic atmosphere. As a result, they confirmed that even at low temperatures, biomass decomposes similarly to the carbonization process and eventually succeeded in improving its quality to a material similar to peat (a type of coal) (Itoh et al., PLoS ONE, 2018).

We also aim to develop a carbonization technology using a self-heating reaction of waste biomass (self-heating carbonization method) (Itoh et al., Waste Management, 2019). Currently, we are investigating the reaction conditions under which the self-heating of biomass occurs and the physical and chemical properties of the biochar produced (Itoh et al., Plos ONE, 2020). Since the heat source for carbonization is extracted from inside the feedstock in this method, the production of biochar can be done without the use of fossil fuels. Thus, the self-heating carbonization method is expected to be an epoch-making technology that will revolutionize the conventional concept of carbonization.

原料乳牛ふん(左)と90℃で作成した牛ふん由来のバイオ炭(中央)。右は無酸素雰囲気下で90℃で加熱した乳牛ふん。(Source: https://doi.org/10.1371/journal.pone.0196249.g002)

Raw dairy cattle manure (left) and biochar derived from cattle manure prepared at 90°C (center). On the right is dairy cattle manure heated at 90°C in an oxygen-free atmosphere.

<Papers>

- Itoh, T., Ogawa, T., Iwabuchi, K., Taniguro, K. Heat balance analysis for self-heating torrefaction of dairy manure using a mathematical model, Waste Management 162, 1–7 (2023).

DOI: 10.1016/j.wasman.2023.03.009 - Itoh, T., Iwabuchi, K., Maemoku, N., Chen, S., Taniguro., K. Role of ambient pressure in self-heating torrefaction of dairy cattle manure, PLoS ONE 15, e0233027 (2020).

DOI: 10.1371/journal.pone.0233027 <OPEN ACCESS> - Itoh, T., Iwabuchi, K., Maemoku, N., Sasaki, I., Taniguro, K. A new torrefaction system employing spontaneous self-heating of livestock manure under elevated pressure, Waste Management 85, 66–72 (2019).

DOI: 10.1016/j.wasman.2018.12.018 <OPEN ACCESS> - Itoh, T., Iwabuchi, K., Ota, K. A new approach to stabilize waste biomass for valorization using an oxidative process at 90 °C, PLoS ONE 13, e0196249 (2018).

DOI: 10.1371/journal.pone.0196249 <OPEN ACCESS>

2.バイオ炭を用いた環境保全型作物生産システムの確立/Establishment of an environmentally friendly crop production system using biochar

作物生産の現場である農地には収量増加を期待し,長年の間,化学肥料が投入され続けています。その一方で,化学肥料製造過程に必要な化石燃料の使用や,過剰量の施肥による環境影響が懸念されており,これまでのエネルギー投入型の作物生産から環境保全型の農業に切り替える必要があります。

この実現には堆肥などの有機肥料を基本とした作物生産システムを構築することが必要不可欠です。有機肥料は人類が古くから利用してきた,良質な肥料ではありますが,化学肥料と比較すると肥効性が低いなどの問題を抱えます。そこで,本研究室では堆肥とバイオ炭を混同施用することで,化学肥料に頼らずとも必要十分量の作物生産ができることを目指し,研究を進めています。

For many years, chemical fertilizers have been applied to farmland, the site of crop production, in the hope of increasing yields. On the other hand, there are concerns about the use of fossil fuels for the chemical fertilizer production process and the environmental impact of excessive fertilizer application.

In order to realize this, it is essential to construct a crop production system based on organic fertilizers such as compost. Organic fertilizers have been used by humans for a long time and are high-quality fertilizers, but they have problems such as low fertilizer efficacy compared to chemical fertilizers. Therefore, our laboratory is conducting research on the mixed application of compost and biochar with the aim of achieving sufficient crop production without relying on chemical fertilizers.

<Papers>

- Piash, M.I., Itoh, T., Abe, K., Iwabuchi, K. Superior nutrient recovery and release by chicken manure-derived biochar over hydrochar and compost for soil fertilization, Geoderma Regional 40, e00906 (2025). https://doi.org/10.1016/j.geodrs.2024.e00906

- Piash, M.I., Uemura, K., Itoh, T., Iwabuchi, K. Meat and bone meal biochar can effectively reduce chemical fertilizer requirements for crop production and impart competitive advantages to soil, Journal of Environmental Management 336, 117612 (2023).

DOI: 10.1016/j.jenvman.2023.117612 - Piash, M.I., Iwabuchi, K., and Itoh, T. Synthesizing biochar-based fertilizer with sustained phosphorus and potassium release: Co-pyrolysis of nutrient-rich chicken manure and Ca-bentonite, Science of the Total Environment 822, 153509 (2022).

DOI: 10.1016/j.scitotenv.2022.153509 <OPEN ACCESS> - Piash, M. I., Iwabuchi, K., Itoh, T., Uemura, K. Release of essential plant nutrients from manure- and wood-based biochars, Geoderma 397, 115100 (2021).

DOI: 10.1016/j.geoderma.2021.115100 <OPEN ACCESS> - Ochiai, S., Iwabuchi, K., Itoh, T., Watanabe, T., Osaki, M., Taniguro, K. Effects of Different Feedstock Type and Carbonization Temperature of Biochar on Oat Growth and Nitrogen Uptake in Coapplication with Compost, Journal of Soil Science and Plant Nutrition 21, 276−285 (2021).

DOI: 10.1007/s42729-020-00359-y

3.よりクリーンなバイオ固形燃料製造および燃焼技術の開発/Development of cleaner biosolid fuel production and combustion technologies

バイオマスを直接燃焼して熱エネルギーを獲得する方法は人類が古くから利用してきた技術であり,最も基本的なバイオエネルギー利用方法です。一方で,低品質なバイオマスを燃焼効率の低いストーブで燃焼させると,PM2.5などに代表される大気汚染物質が発生し,これに関連した年間死者数が420万人に達した(2015年)とされています。このような状況を改善するため,本研究では燃焼時のPM2.5排出リスクの低いバイオ固形燃料の製造や燃焼技術の開発を目指しています。

The direct combustion of biomass to obtain heat energy is a technology that humans have used since ancient times and is the most basic method of bioenergy utilization. On the other hand, when low-quality biomass is burned in stoves with low combustion efficiency, air pollutants such as PM2.5 are generated, and the number of deaths related to this has reached 4.2 million per year (2015). To improve this situation, this research aims to develop manufacturing and combustion technologies for bio-solid fuels with low risk of PM2.5 emissions during combustion.

<Papers>

- Dalkhsuren, D., Iwabuchi, K., Itoh, T., Narita, T., Piash, M.I., Nachin, B., Sukhbaatar, G. Effects of Ash Composition and Combustion Temperature on Reduced Particulate Matter Emission by Biomass Carbonization, BioEnergy Research, (2022).

DOI: 10.1007/s12155-022-10526-x - Itoh, T., Fujiwara, N., Iwabuchi, K., Narita, T., Mendbayar, D., Kamide, M., Niwa, S., Matsumi, Y. Effects of pyrolysis temperature and feedstock type on particulate matter emission characteristics during biochar combustion, Fuel Processing Technology 204, 106408 (2020).

DOI: 10.1016/j.fuproc.2020.106408 <OPEN ACCESS>

廃棄物系バイオマスの堆肥化による有機肥料製造と生物脱臭/Composting of waste biomass to produce organic fertilizer and biological deodorization

堆肥化は原料となる廃棄物の多様性が大きく,また特定の微生物のみを利用する反応系とは異なる開放系の反応ですので,環境温度なども含めて外界の影響を受け易いプロセスです。一方では外界である環境中に常在する微生物をそのまま利用できることが堆肥化の長所でもあり,バイオマスの物理性や常在微生物の反応特性を分析し,堆肥化反応を促進させる方法の考案を目的にしています。また堆肥化に付随して生じる悪臭対策として,アンモニアを吸着する微生物脱臭のメカニズムを解明し,低コストかつ低エネルギーな堆肥化システムの構築も行っています。

Composting is a process that is easily affected by the outside world, including environmental temperatures, because of the great diversity of the waste materials used as raw materials and because it is an open system reaction that differs from a reaction system that uses only specific microorganisms. On the other hand, the advantage of composting is that it can utilize microorganisms indigenous to the environment, which is the outside world. In addition, as a countermeasure against bad odors associated with composting, we are also working to elucidate the mechanism of microbial deodorization that adsorbs ammonia, and to construct a low-cost, low-energy composting system.

<Papers>

- Shin, Y., Iwabuchi, K., Itoh, T.

Low-temperature biochars are more effective in reducing ammonia emissions through various mechanisms during manure composting.

Journal Material Cycles and Waste Management 26, 138–148 (2024).

https://doi.org/10.1007/s10163-023-01808-3

マイクロスケール機械工学を活用した「バイオガス」と「メタン発酵消化液」の移動現象の解析とその応用に関する研究/Research on analysis of migration phenomena of “biogas” and “methane fermentation digestate” using micro-scale mechanical engineering and its application

メタン発酵施設を自給エネルギー生産の方法として展開させていく上で求められる技術的課題や成立要件からは,メタン発酵消化液の処理の問題や,高効率で安価な発酵法・メタン精製装置設計・開発が重視されます。本研究テーマでは,「バイオガス」と「メタン発酵消化液」のマイクロ現象の解析とモデル化,「メタン発酵消化液の噴霧乾燥」を進めて,新しい微粒子素材を合成することを目標に,1.コンパクトなバイオガス精製装置設計のモデルの構築,2.噴霧乾燥で得られるメタン発酵消化液粉末(微粉末)の特性の解明を行っています。マイクロスケール機械工学によるバイオマス技術研究に求められる基礎と「バイオマス素材化」及び「エネルギー生産」の実用をつなぐ研究を行っています。

The technical issues and requirements for the development of methane fermentation facilities as a method of self-sufficient energy production place emphasis on the treatment of methane fermentation digestate and the design and development of highly efficient and inexpensive fermentation methods and methane purification equipment. In this research theme, we aim to synthesize new particulate materials by analyzing and modeling the micro phenomena of “biogas” and “methane fermentation digestate” and spray-drying methane fermentation digestate, and to develop: 1. a compact biogas purification system design model, 2. a methane fermentation digestate obtained by spray-drying, and 3. a methane fermentation digestate (fine powder). We are also investigating the characteristics of the methane fermentation digestate powder (fine powder) obtained by spray-drying. We are conducting research that links the fundamentals required for biomass technology research with the practical applications of “biomass materialization” and “energy production” by means of micro-scale mechanical engineering.